Request Info

Are you looking for something like this? We've got you covered. Complete the form below, and we'll get back to you about your project. If you'd rather give us a call at 800-874-8326, be sure to mention the reference number below.

REFERENCE: 20-0103

3 Monitor Video Flypack w/Slide Out Work Surface

This case was built as a video presentation hub for corporate shows. The case features 2 – 27” iMac computers, a 32” multi-view monitor, custom IO panels, slide out work surface, and an equipment rack.

The monitor and computers are mounted on custom built mounts based around Chief K2W120B articulating arms. The arms are mounted on custom folding aluminum upright poles. The mount assembly features a locking system that allows the height to be adjusted with a simple tech-lock style handle. The mount stays attached to each monitor during transport to allow for simple set up and tear down without the need for tools. The mount/monitor assembly is designed to slide onto the pole. The traveler piece that interfaces with the upright pole is lined with UHMW plastic to ensure smooth operation. The upright poles are designed to fold down during transport to keep the top lid height to a minimum.

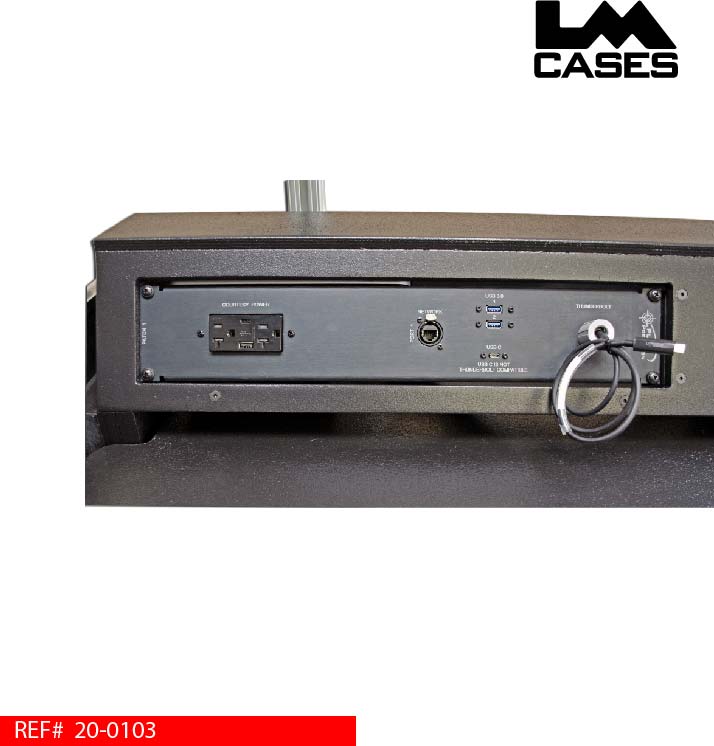

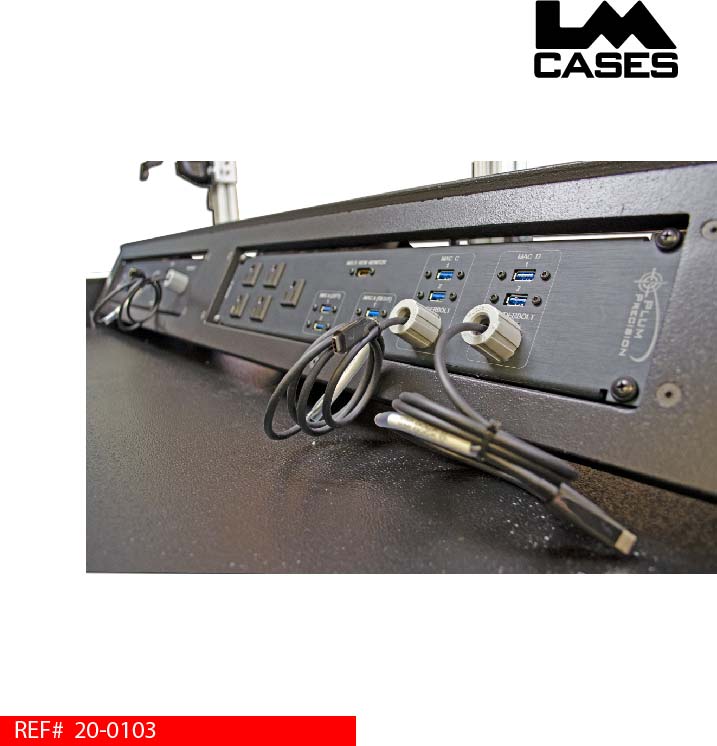

3 custom built, rack mounted IO panels are mounted in a rear angled chassis to interface with the 2 iMacs and Multiview monitor. Power is provided to each iMac via its corresponding panel below each computer. A tethered Thunderbolt 3 cable is mounted in each panel allowing the corresponding iMac to interface with other components in the case without the need for multiple connections. A Thunderbolt dock is mounted to each panel allowing additional connections like ethernet and USB to be addressed at the panel. This allows for a cleaner look with only a single cable between the case and the iMac. A custom loom with a HDMI and locking IEC cable is provided for the Multiview monitor.

The center IO panel features 5 spaced AC outlets. These are designed to accommodate larger power supplies that may block other outlets if they were used in a typical duplex configuration. The system is designed to work with the 2 mounted iMac computers and 2 MacBook Pro laptops on the slide out work surface. 2 additional banks labeled C & D on the center IO panel provide Thunderbolt and USB for these laptops. The Thunderbolt cables can provide power for the laptops in addition to signal to help keep the work surface neat.

The slide out work surface is 68” wide x 21” deep. It features a locking multi-point latch system allowing it to be extended and locked into place in 1” increments. The work surface face piece contains a 1RU rack section for a ClearComm base station. A custom XLR loom with a locking IEC was provided to extend the com connections into the rack section.

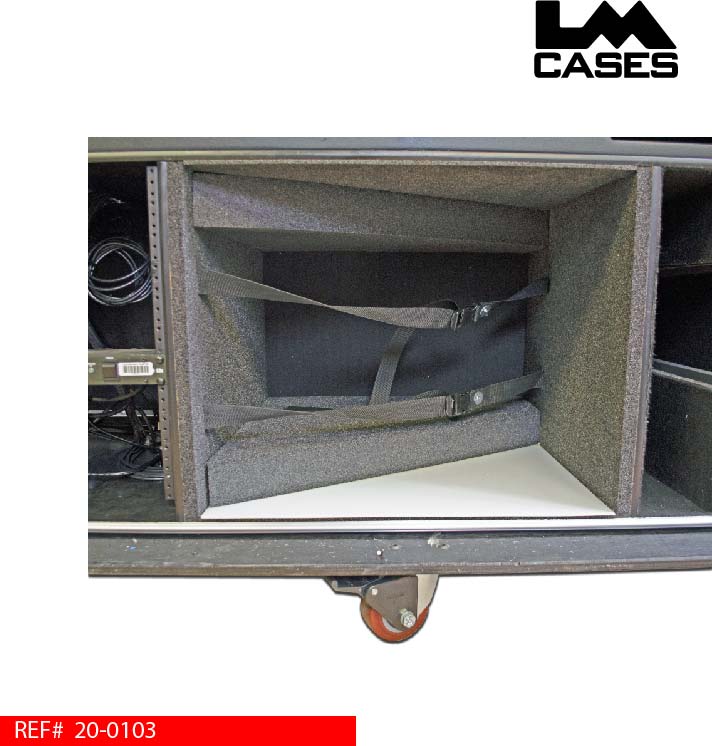

Each iMac is held with its mount arm attached in a custom CNC cut foam compartment. The foam used in each compartment is a special non-abrasive type to prevent abrasion to the screen or aluminum chassis. The mount is supported in a way that prevents transient stress from transferring from the mount to the iMac.

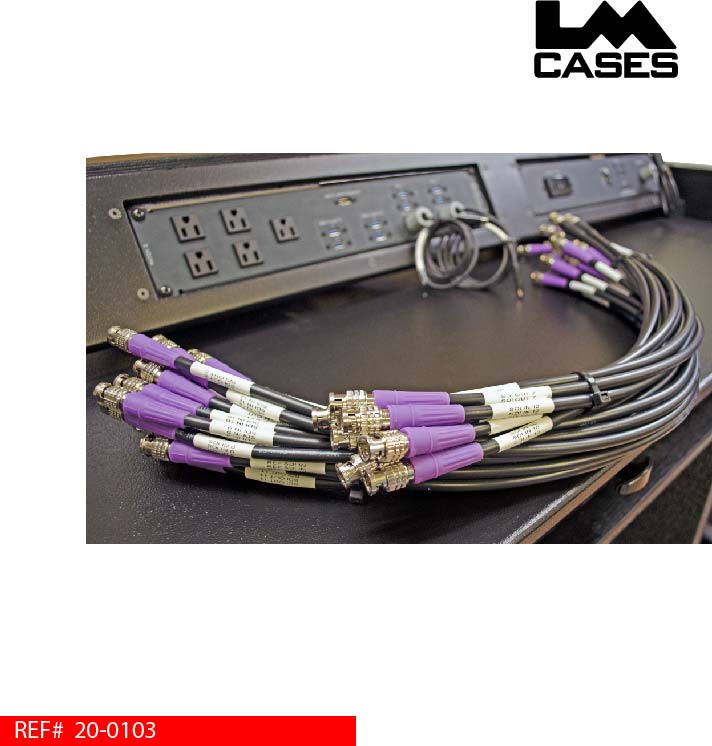

The 32” Multiview is stored at an angle in the center compartment. An 11RU rack is provided for equipment storage. A side mounted 3RU patch section is provided for a custom IO panel built by the LM Cases Custom Integration department. The 3RU panel includes 75ohm Neutrik BNC jacks to interface with the internal components. Custom 12k BNC cables were built with individual labels to wire the panel to the internal equipment. Purple back boots were used to match Plum’s corporate purple color. XLR output jacks are provided for a main audio output. Power is brought into the system via a Powercon jack. A custom adapter plate was used allowing the customer to swap the Powercon jack out with a recessed Hubbell 5278 inlet in the future if needed.

The exterior case is built from ½” plywood laminated with black ABS plastic. The case rides on 4” x 2” Colson HD casters and features deep recessed hardware. Custom silkscreens of the Plum Precision logo are printed on the case.

Special thanks to Brian and the Plum team for a great project!

- REFERENCE: 20-0103

- CATEGORY: Audio/Visual CATEGORY: Custom Integration